Ron Ziessler breathes new life into his epic HQ Holden after it sat idle for 23 years!

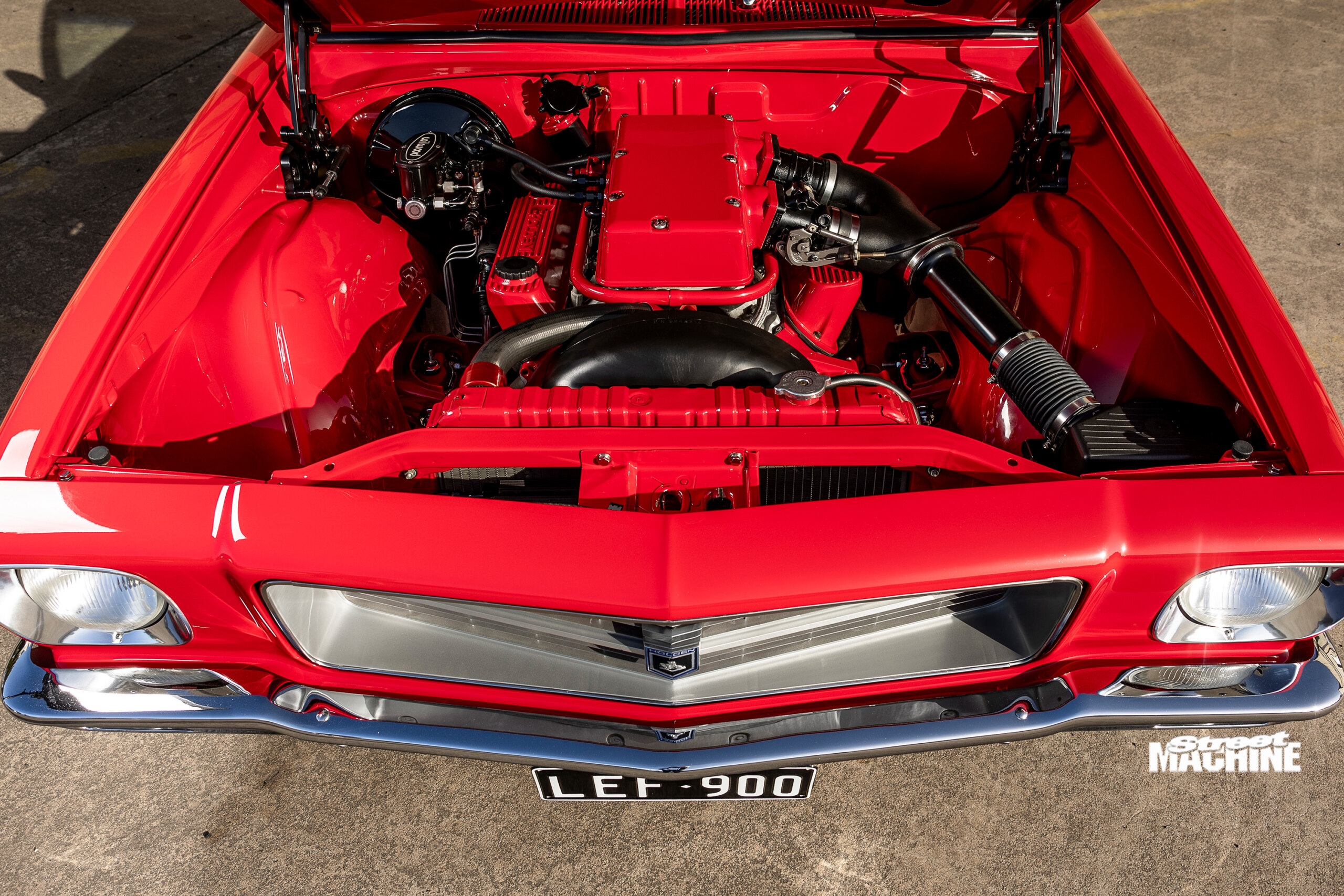

When we featured Ron Ziessler’s HQ Holden way back in the August 2000 issue of Street Machine, we said that “DIY streeters don’t get much better than this”. Boasting flawless red paint and slung low over a set of Weld Draglites, powered by a thumping Iron Lion V8 packed with Group A goodies, and detailed to within an inch of its life, the car was a bona fide shed-built stunner that claimed quite a bit of tinware during its 12 months on the scene.

First published in the December 2023 issue of Street Machine

Soon after he finished the car, Ron’s family began to grow and his priorities shifted, so he mothballed the Quey for two-and-a-bit decades. “After its second show, I parked it up,” he says. “Life ebbs and flows; when I showed it the first time, my wife was pregnant with our first child. I was driving it a little bit, but then my kids became my focus. Most of my friends moved on from cars for the same reason, but it never crossed my mind to sell it.”

We were amazed to see the Quey finally break cover at Meguiar’s MotorEx 2023, still looking as stunning as ever. But there was a lot more involved in reviving the car than simply blowing the dust off it, charging the battery and hitting the key.

“In May 2022, my brother-in-law Pete said, ‘Isn’t it about time?’” Ron grins. “I figured he was right, so I pulled the HQ out of its corner, and that’s when the work started.”

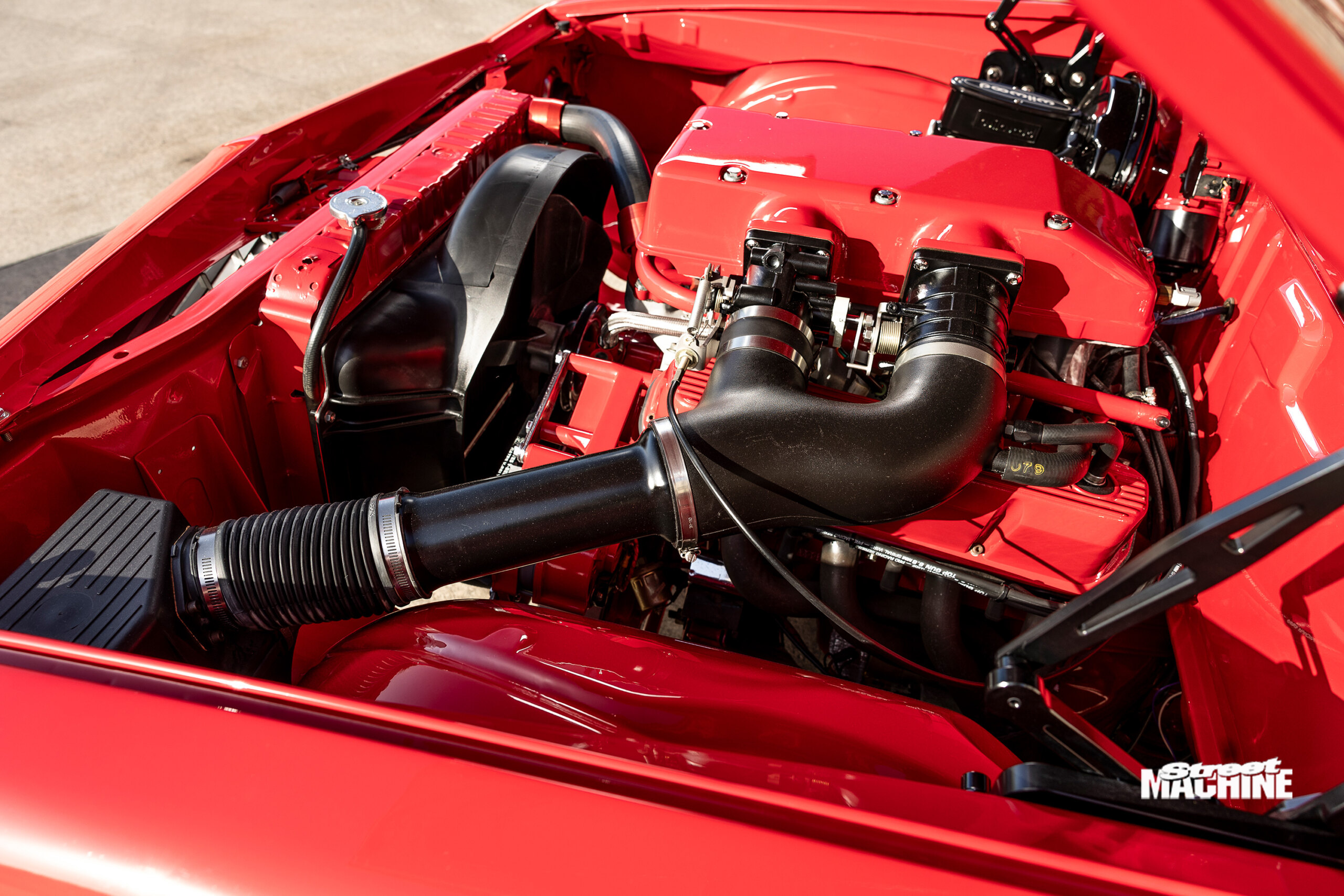

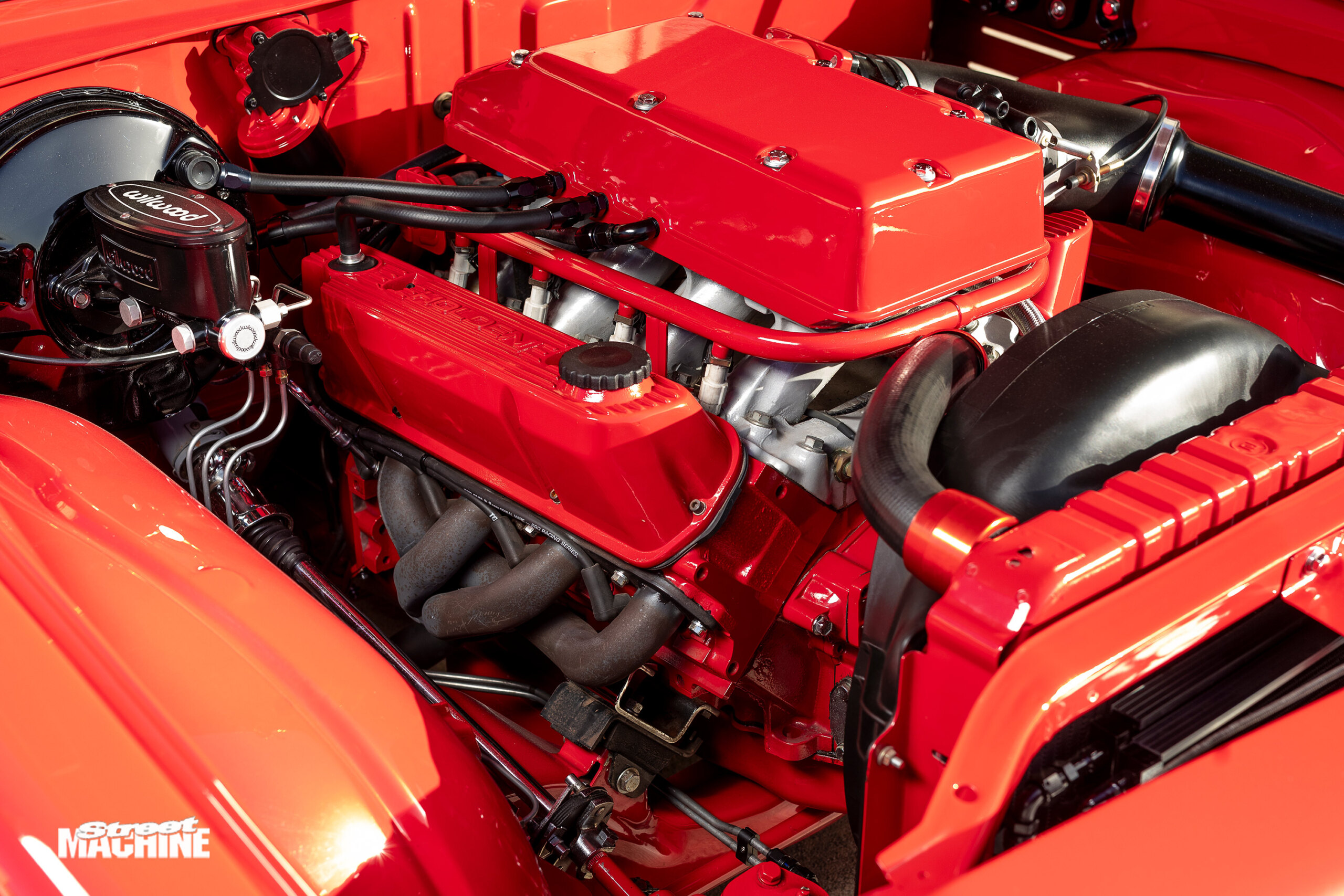

The first order of business was convincing the spicy Holden V8 to fire into life for the first time in a long time. Back in the day, Ron bought all the good bits for the engine from a bloke who worked for one Larry Perkins. Hardware like the D-port VN Group A cylinder heads, Group A rods and ‘Larry-grind’ camshaft came as a package deal, along with the holy grail of Holden V8 performance – the VL Walkinshaw twin-throttlebody manifold. It was a gem of an engine that made ample power and revved to 7500rpm, and with limited funds available, Ron took every measure to avoid a rebuild.

“I pulled the plugs out, put oil and CRC down the bores, filled the engine full of oil and started slowly turning it over by hand over the course of a week; surprisingly, it turned over easily,” Ron says. “In the meantime, I got the injectors serviced and flushed out the fuel rails, and running off a jerry can, it fired on the second shot. I was happy with that, given it last ran in 2003!”

The fuel system was cactus. The tank was internally rusted and full of glugged-up 98, and the rubber lines had perished and were leaky. A custom alloy tank with an internal pump was built by Steve at MKAL Automotive, then the entire system was replumbed front-to-back with new lines and fittings.

Ron then turned his attention to the brakes. “Everything was seized, stuck, rusted or corroded,” he says. “I rang Johnny at Pro9 and ordered a full set of Wilwood brakes, fitted them up, made all-new brake lines from front to rear and replaced the brake booster.”

Back in the day, the rear end was done by John Taverna, and, impressively, while the car sat on the deck and the wheels carried meaty 295/50R15 tyres, it retained factory-style HQ coil springs, shock absorbers and trailing arms. Ron wanted it all to look stock to avoid run-ins with the law, but this time around he opted to add Pro9 adjustable trailing arms to the mix.

Ron was happy with his flash new anchors, but bitterly disappointed when it came time to re-fit the old Draglites. “They didn’t clear the calipers!” he recalls. “I had already bought new tyres because the old ones were dry-rotted, and after days of umming and ahhing over wheels, it came down to what I could afford, which were the Street Pros.”

The wheels give the car a more contemporary vibe, with less chrome and more black – a theme that Ron decided to roll with, especially when he realised that much of the chrome work from the original build was no good. “I sent the bumpers out to be rechromed, but the rest of it couldn’t be saved, so I stripped and repainted it instead,” he says.

While the hot Holden five-litre happily burst back into life like it was 1999, the Trimatic transmission wasn’t quite so willing. “It was full of neutrals!” Ron says. He sent it out to be rebuilt, taking the opportunity to convert it from a full-manual valvebody back to automatic, and taming the Dominator converter down to a more streetable 3800rpm stall speed.

Mechanically, the car was back to its former glory, but with MotorEx looming and Ron keen for the Quey to look its Sunday best, the finer details came into focus. He repainted the exhaust system and polished the mufflers, then spent countless hours polishing the stainless bolt heads; disassembling, cleaning and reassembling components; and replacing parts like the wiper motor, which had failed through lack of use.

“The body mount bushes had disintegrated, and replacing them meant separating the body from the chassis, which was a fun job!” Ron remarks. “The last thing in the days before MotorEx was the paint touch-ups, of which my mate Cam Beller at Beller Motorsport did an amazing job. Even in storage, shit happens!”

With the HQ looking resplendent in the hall at MotorEx, Ron had the opportunity to sit back and admire the car that he’d first built over 20 years ago finally restored to its former glory. “I was blown away by the number of people who told me they remembered it from the feature in Street Machine all those years ago,” he says. “The response was just nuts. I will say that I discovered how much things cost these days; I think I spent the same getting the car back on the road as what I spent building it in the first place!”

Now that the HQ is back in service, Ron has some changes planned to make it a little more driveable – things like ditching the Delco ECU for a Haltech, and adding power steering and perhaps even airbags.